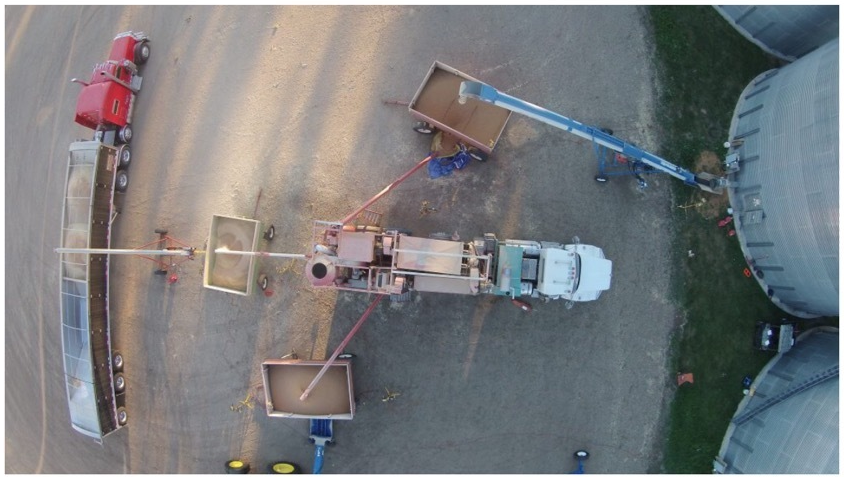

How Our Machine Works

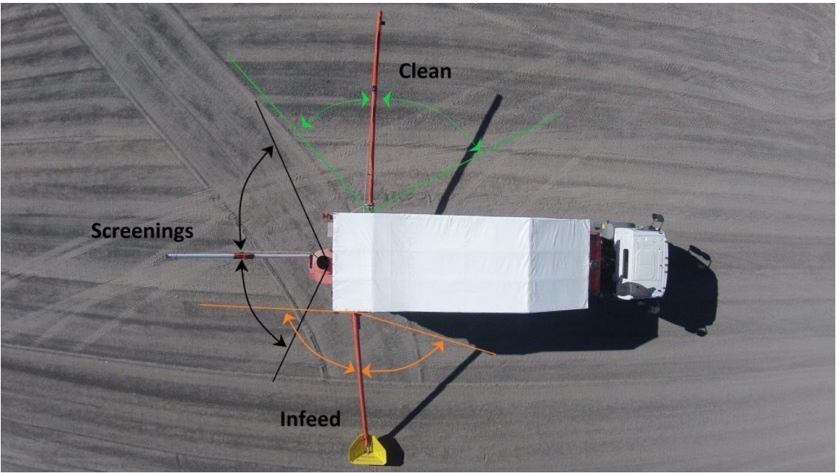

How it flows through the machine:

- Our indeed auger (which pivots 180 degrees) receives the grain that flows into the machine.

- Scalper screens which removes large foreign objects (sticks, straws, and rocks).

- Aspirators which creates a curtain of grain that removes all the chaff & dust.

- Length graders that sizes the grain by length, giving the ability to remove any foreign objects longer than the wheat.

- The grain flows into the screens, composed of 2 rotary screens driven by impellers, forcing the small & cracked seeds out through the openings in the screen which in turn are cleaned every rotation by rubber scrapers which ultimately sizes the grain by width.

- The mechanical weigher weighs the cleaned product.

- The 2nd Aspirator removes any remaining fine dust.

- Clean grain is augured away from the machine (it can pivot approximately 160 degrees).

-

- All screenings are fed into the center auger that runs down the middle of the truck and then augured away from the machine. (The auger can pivot 180 degrees as well)

Our machines are completely self-contained, they have their own generators for power and weighers built into the machine so there is no need to drive to a scale.

The grain flows continuously through the machine, so there is no capacity for storage.

Harvested grain is usually fairly clean.

Usually being the operative word, as this is dependent on a number of critical factors: the correct settings and capacity being used, the grain being dry, no heat damage taking place and kernels not being broken during the harvesting process - many factors, which are difficult to control. In addition, the quality of grain begins to deteriorate as soon as it has been harvested, so it is imperative that dirt and impurities are removed to delay the deterioration process and ensure that the stored grain is of high quality for end-users. It is therefore highly recommended that harvested grain is passed through a grain cleaner and/or pre-cleaner in order to ensure that the quality of the grain is optimized before it goes into storage.

Pre-cleaning grain before storage plays two vital roles:

- Adding value to the grain through the removal of dirt, impurities and damaged particles.

- Ensuring a longer life of the grain while it is in storage.